Trough chain conveyor HT

low carry-over and easy to clean

Type HT trough chain conveyors are designed for small conveying quantities. The bulk materials can be transported horizontally or slightly uphill.

The HT type trough chain conveyors are easy to clean and designed to minimise product carry-over.

Starting with our standard modular-system we adapt the chain conveyor to the product characteristics, the installation situation and the process requirements.

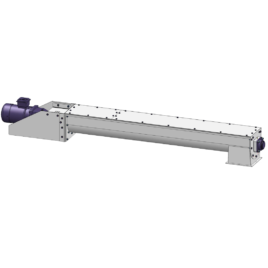

Trough chain conveyor HTBasic design

- Space-saving bevel geared motor in slip-on design

- Low carry-over, as the scrapers stripe off the trough completely

- No gaps in the trough, since it is folded from a single piece

- Take-up end with low dead space, the tensioning unit is integrated into the driving station

- Scrapers made of white polyethylene 1000, FDA-compliant for foodstuffs

- Troughs outside painted, inside untreated

- Overflow valve with safety switch and inspection window

Chain conveyor type HT technical data

| Chain conveyor | KF170HT | |

|---|---|---|

| Trough width | mm | 170 |

| Intended JACOB pipework Ø | mm | 150 |

| Capacity for grain 0.75 t/m³ |

||

| Max. fill height | mm | 100 |

| Nominal capacity at 0.45 m/s (66 rpm) with length max. 27 m and 2.2 kW |

t/h | 15 |

| Max. capacity at 0.35 m/s (50 rpm) with length max. 43 m and 1.5 kW |

t/h | 8 |

| Material thickness in the standard design | ||

| Trough | mm | 3 |

| Cover | mm | 2 |

| Chain characteristics |

||

| Chain breaking force | N | 45000 |

| Chain pitch | mm | 41.4 |

| Chain wheel, number of teeth | 10 | |

| Weights of the elements with chain | ||

| Driving station with geared motor and without material to be conveyed | kg | 43 |

| Take-up end without material to be conveyed | kg | 21 |

| Trough empty | kg/m | 30 |

| Trough at max. fill height with 0.75 t/m³ of grain | kg/m | 48 |

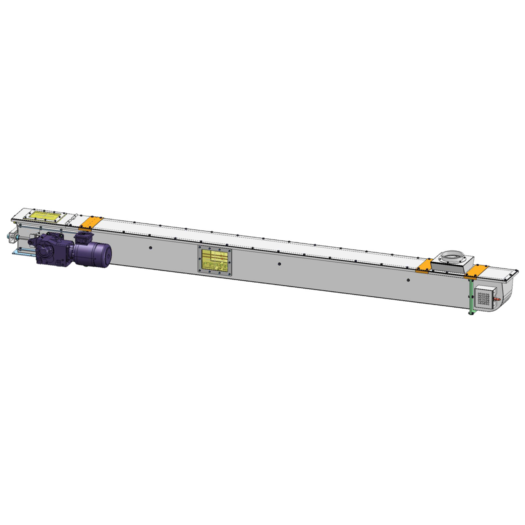

Chain conveyor HT design and accessories

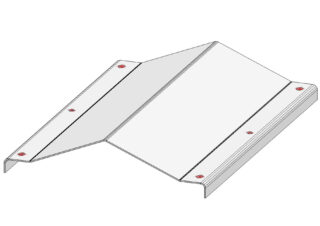

Roof-shaped cover

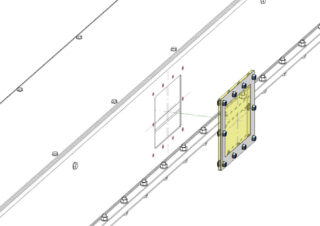

Inspection window

Gear oil: mineral oil or synthetic (food compatible)

Operating instructions

German or English

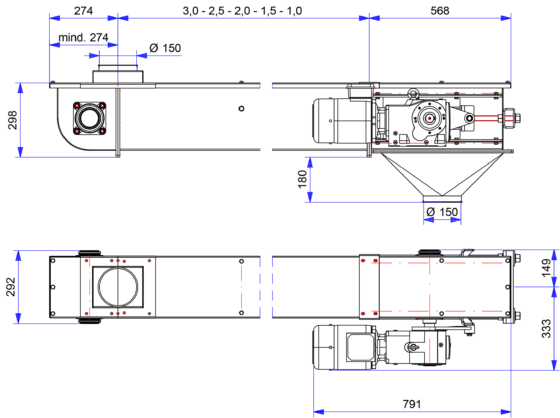

Dimension drawning for chain conveyor HT

The dimensions and connection dimensions of our trough chain conveyor type HT can be found in the dimension drawing.

Examples from our production

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: Chain conveyorChain conveyorsConveying technologyTrough chain conveyors

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Login

Login