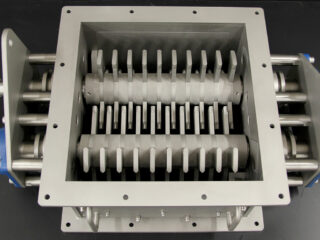

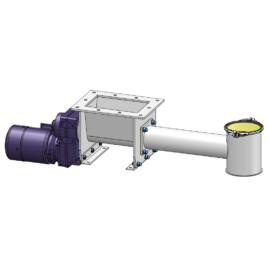

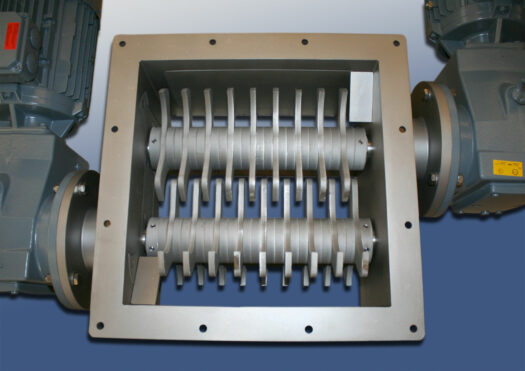

Lump primary crusher

precrushing of agglomerates and lumps

The robust KVB series primary lump crushers are suited to the coarse grinding of agglomerates and lumps which are hard and brittle.

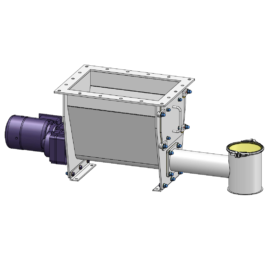

Should the product still be too coarse after the primary crusher, we recommend using our MKB lump crusher to grind the coarse goods to the desired final grain size. Thanks to its modular construction the two lump crushers can be built on in a downstream and space-saving manner.

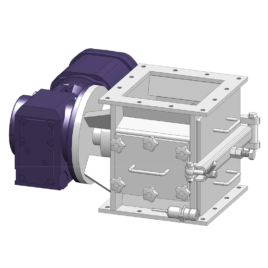

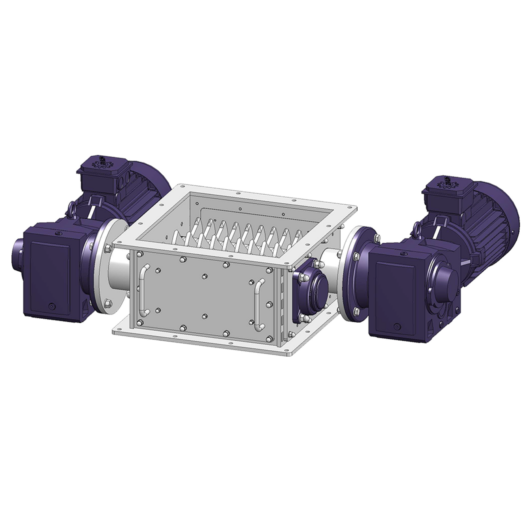

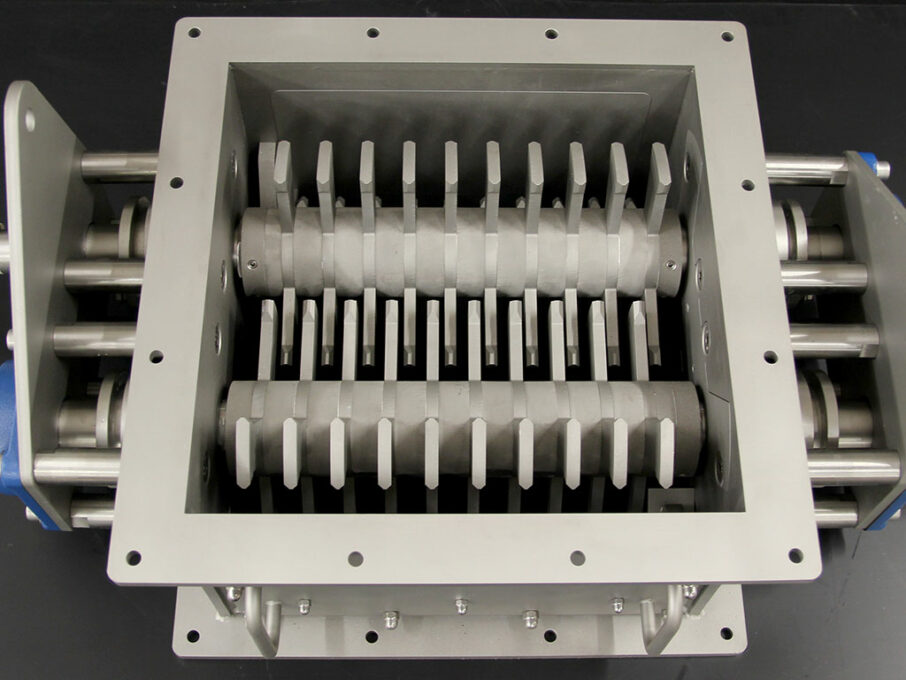

Lump primary crusherBasic design

- Standard sizes: 400 x 400 mm to 800 x 600 mm

- Capacity up to 30m²/h, other capacities on request

- Very stable construction with low dead space

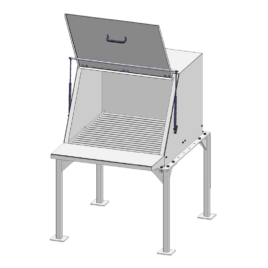

- Large lateral openings for cleaning and inspection

- Shaft sealing by radial shaft sealing rings or packing glands

- Load transmission by means of coupling or directly with shaft-mounted gear motor

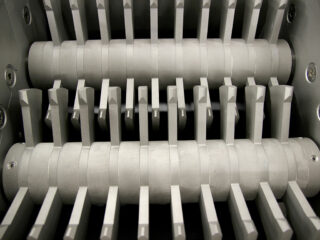

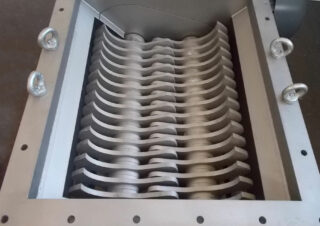

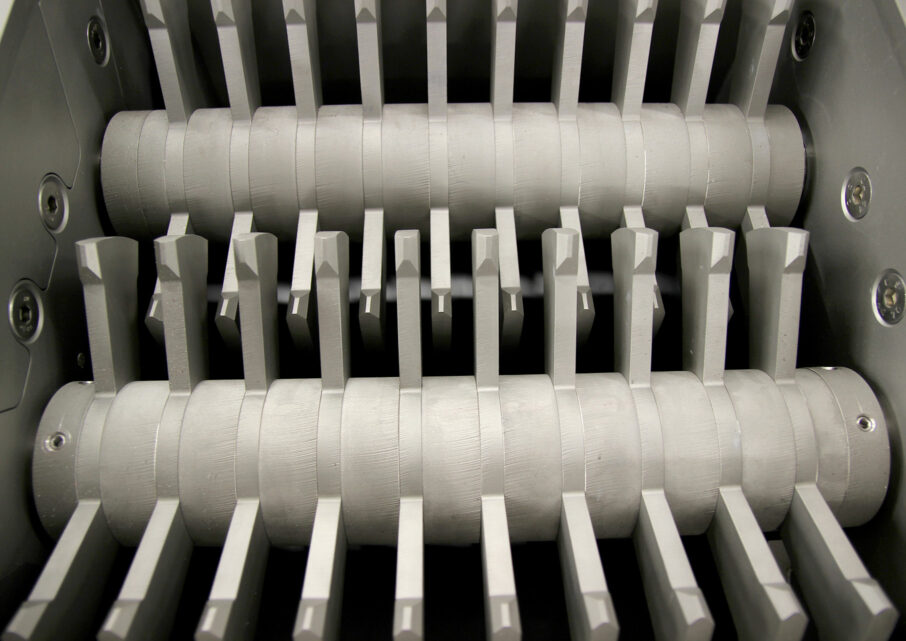

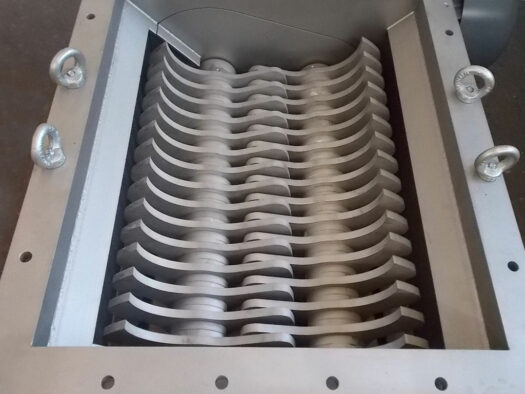

- Various crusher fittings for final grain sizes larger than 15 mm

Function

Up until the comb bar the coarse product is crushed by rotating beaters and discharged downward through the comb openings.

Areas of use

In principle all brittle, hard or frozen products can be milled up to a grain size of >15 mm.

Characteristics

- Easy to clean

- Low maintenance effort

- Adaptable for different products and grain sizes with changeable crusher fittings

Options

- Single or dual shaft design

- Material: stainless steel 1.4301, 1.4571 or steel

- Crushing tools made of wear resistant steel

- Surface design: glass bead blasted

- Chassis, control unit, inlet and outlet funnel, adapter pieces (round to square)

Examples from our production

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: Lump primary crusherLump shredderPrimary crusherProduct crushingShredder

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Login

Login